Ultrasonic Immersion Testing Tanks

These Andec tanks, from the smallest tank made for demonstration in Ultrasonic teaching schools, to the largest ones, feature the latest advanced testing modes available for aircraft and other components. High speed and highly accurate relocation of single or phased array transducer groups make these tank systems preferred in immersion testing for any component application. Clicking on any one in the following list, shows photographs and a description of the Andec Immersion testing tanks.

Four Axis Ultrasonic Immersion Testing System with Very High Relocation Accuracy

This system is designed for the inspection of critical aircraft engine disks and other circular components. Each axis is driven by a precision servo motor.

All axes run on precision linear bearings.

A bottom mounted manual or motor driven precision rotary table with part clamping arrangement is provided for the inspection of round and cylindrical parts.

Thick windows on both sides of the tank allow for the easy observation and placement of parts.

After removal from the water wet parts can be placed conveniently on acrylic plates, located on the top of the frame near each end of the tank.

One of the earlier tanks is shown with dimensions of 1525mm (5’) long, 1225mm (4’) wide, and 765mm (2.5’) deep.

Can be supplied in any dimensions.

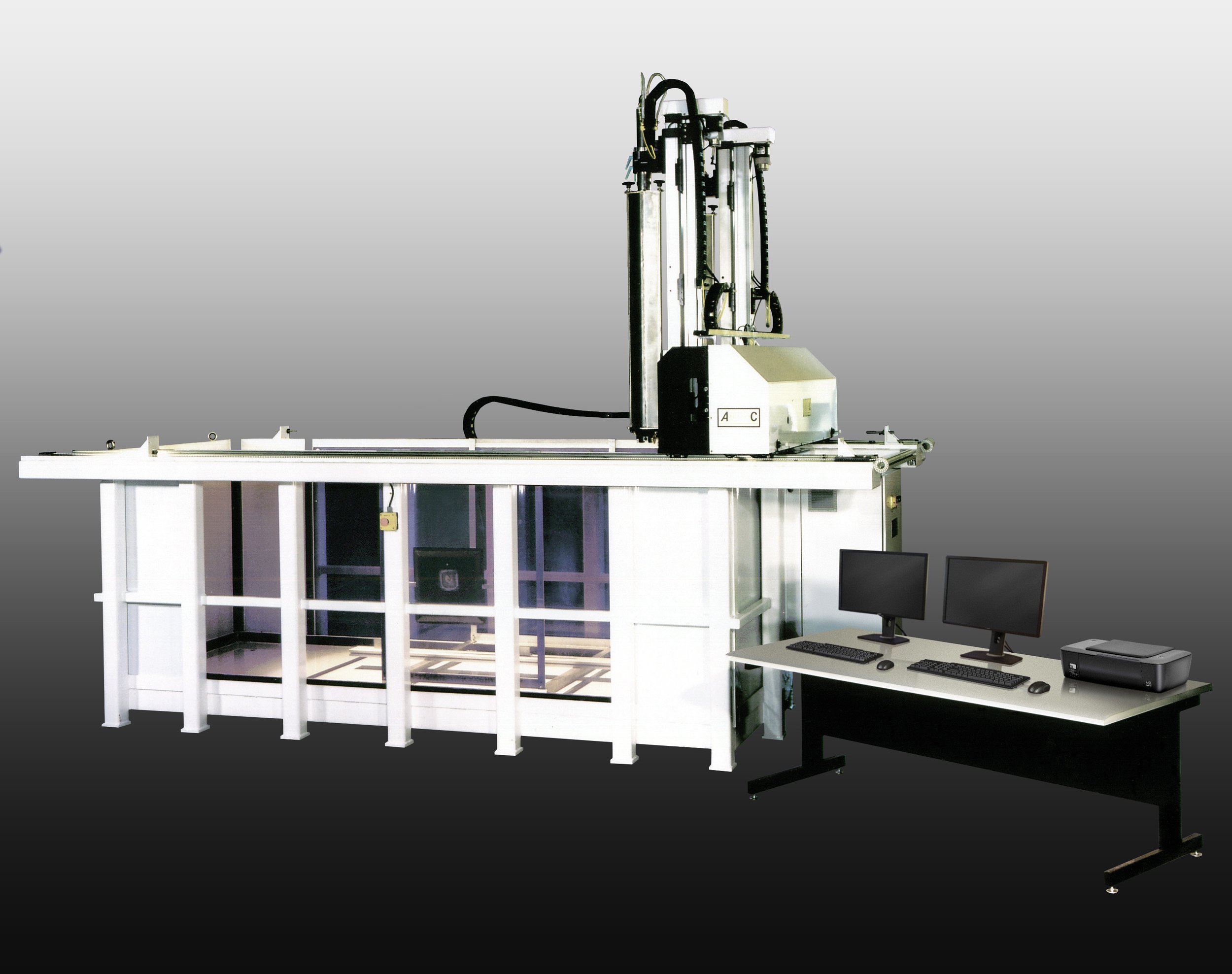

Ultrasonic Immersion Testing System for Aircraft Engine Fan Disks and Spools

This high speed, precision, seven axis, Ultrasonic Immersion and submerged Eddy Current scanning system, was initially designed for the inspection of aircraft engine disks and spools.

Bridge, carriage and search arm are capable of scanning in X,Y,Z & R modes.

Bottom mounted precision rotator, including part holding clamping arrangements.

Approved to critical engine manufacturers’ standards.

Inside dimensions 1525mm (5’) wide, 1525mm (5’) long and 1220mm (4’) deep.

Can be supplied in any practical dimensions, with multiple axes and the latest Ultrasonic, or Eddy Current instrumentation and software control.

Ultrasonic Immersion Testing system for Small Parts Testing or Educational Teaching Purposes

This small tank is in use at several educational organizations to demonstrate and teach the principles of Ultrasonic Immersion Testing.

It has manual (or motor-driven) X, Y and Z movements running on precision ground stainless steel rods and linear bearings, with easy hand controls.

An X, Y manipulator can be mounted on the submerged end of the long stainless steel search tube, which can be tilted for angular transducer positioning, and also rotated.

The tank has four clear acrylic windows, providing easy demonstration of test part positioning and transducer orientation.

After removal from the water, wet parts can be placed conveniently on acrylic plates located on the top of the frame near each end of the tank.

Can be supplied in various sizes, while the smaller tanks can have removable legs for easy transportation or shipping between class locations.

Multi Axis Ultrasonic Immersion or Waterjet Scanning System for Composite Panels

This system has two long independent manipulator arms and gimbled transducer holders, using Andec patented “Laminar Link” coupling devices in the empty tank, or with full immersion in the water filled tank, to inspect flat and contoured composite panels, tubes, and other parts, with pulse echo or through transmission.

Inside dimensions of the heavy stainless-steel tank, with thick acrylic viewing windows along most of the lengths on both sides, as initially installed and shown, were 6100mm (20’) long, 1830mm (6’) wide and 1675mm (5.5’) deep. Length was later extended to 12200mm (40’) long, and instrumentation replaced with late model units and with the software updated for the latest equipment operation.

Can be supplied in any practical dimensions.

Most of the Andec immersion or water squirter scanning systems are supplied with the special Andec couplant water conditioning pumps and tanks, which guarantee air bubble free clear clean water, with constant pressure.

Ultrasonic Immersion Testing System for Large Steel Bearing Races

This computer-controlled system is supplied with a tilted roller system on which each bearing race is supported and rotated.

As a part of the race moves through the water in the tank, a special scanning mechanism moves the Ultrasonic immersion transducers in a fixed helix across the race surface to detect internal flaws and surfaces defects.

Extremely sturdy construction provides the capability to test a range of diameters from 200mm (8”) to about 1525mm (60”).

Note: The shape and dimension of test parts in photo have been altered